Throughput

Definition:

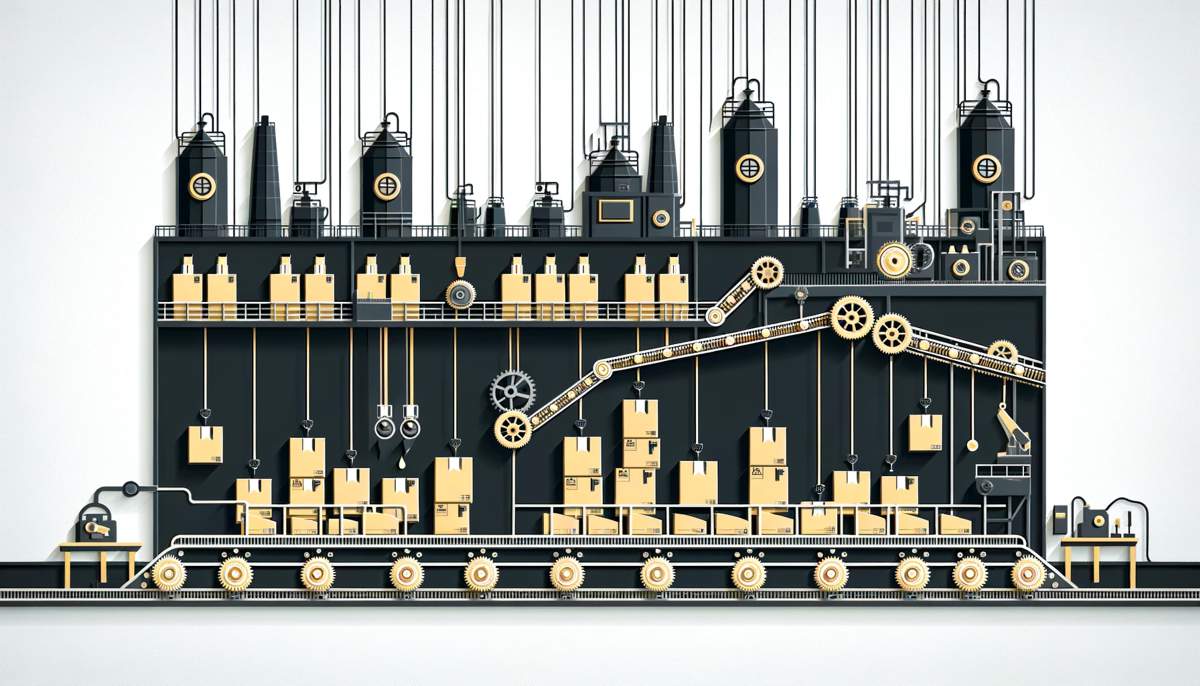

Throughput, in the context of business performance, refers to the rate at which a company completes a process, task, or produces goods within a specified period. This KPI is vital for assessing operational efficiency and productivity.

Purpose:

The primary purpose of measuring Throughput is to gauge the effectiveness of a company’s production or operational processes. It serves as a crucial metric for understanding how well resources are being utilized to generate outputs, be it services or products. By tracking Throughput, businesses can identify bottlenecks, optimize workflows, and improve overall efficiency.

Relevance:

In today’s fast-paced business environment, particularly in manufacturing, logistics, and service-oriented sectors, Throughput stands as a critical measure. It’s not just about the quantity produced; it’s about the speed and efficiency of production. For a manufacturing firm, higher Throughput means more products are being produced in less time, which can directly impact profitability. In service industries, it could mean serving more customers or completing more tasks, enhancing customer satisfaction and competitive advantage.

Key Components and Calculation:

Formula:

The basic formula for calculating Throughput is:

Throughput = Total Output / Total Time

Components:

- Total Output: This represents the total number of units produced or tasks completed in a given period.

- Total Time: This is the time taken to produce these units or complete the tasks.

Data Sources:

Data for Throughput calculation can be sourced from production logs, time tracking tools, and operational databases. It’s crucial to ensure that data is accurate and timely for reliable KPI tracking.

Example Calculation:

Consider a hypothetical company, XYZ Corp, that manufactures widgets. In a week (168 hours), they produce 840 widgets.

Thus, Throughput = 840 widgets / 168 hours = 5 widgets per hour.

Interpretation and Benchmarking:

How to Read the Results:

Understanding Throughput results involves more than just looking at the numbers. It’s essential to compare them against set targets or industry standards. A higher Throughput rate generally indicates better efficiency, but it should be analyzed in context with other factors such as quality, cost, and resource utilization.

Benchmarking:

Benchmarking Throughput involves comparing your figures with industry averages or competitors. This comparison can provide insights into where your operations stand in terms of efficiency and productivity.

Good vs. Bad Results:

Good Throughput results mean meeting or exceeding industry benchmarks or internal targets without compromising quality or incurring excessive costs. On the other hand, lower Throughput could indicate inefficiencies, resource constraints, or process bottlenecks that need addressing.

Use Cases and Applications:

Practical Uses:

Throughput finds its application across various industries, demonstrating its versatility as a KPI. In manufacturing, it’s used to measure the rate of production output. In the service sector, Throughput can indicate the number of customers served or transactions processed within a given time. In IT and software development, it could refer to the number of tasks or projects completed in a sprint.

Real-Life Examples:

- In a car manufacturing plant, Throughput could be the number of vehicles assembled per day.

- For a call center, it might be the number of calls handled per hour.

- In a software development team, Throughput might be measured as features developed per sprint.

Link to Business Objectives:

Aligning Throughput with business objectives is crucial. For instance, if a company aims to increase market share, improving Throughput can lead to higher production without compromising quality, thus meeting increased market demand efficiently.

Benefits and Limitations:

Advantages:

- Enhanced Productivity: Throughput is a direct measure of productivity, helping businesses identify and leverage their operational strengths.

- Cost Efficiency: By optimizing Throughput, companies can better utilize resources, thereby reducing waste and lowering costs.

- Improved Decision Making: Throughput data helps in making informed decisions about process improvements, capacity planning, and resource allocation.

Limitations:

- Quality Overlooked: Focusing solely on Throughput can sometimes lead to a compromise in quality. It’s essential to balance both.

- Context-Dependent: Throughput needs to be interpreted in the context of other factors like market demand and capacity constraints.

Common Misconceptions:

- One misconception is that Throughput alone can determine a company’s profitability. While it’s a crucial factor, it must be considered alongside other financial KPIs.

- Another is that high Throughput always equates to high efficiency. This is not always true, as factors like quality and cost must also be considered.

Strategies for Improvement:

Optimization Tips:

- Streamline Processes: Eliminate bottlenecks and streamline workflows to improve Throughput.

- Invest in Technology: Automation and advanced technologies can significantly enhance Throughput.

- Employee Training: Skilled and well-trained employees can work more efficiently, thus improving Throughput.

Actionable Steps:

- Conduct a thorough analysis of your current processes to identify inefficiencies.

- Set realistic improvement targets based on industry benchmarks.

- Implement changes incrementally, monitoring the impact on Throughput.

Case Study:

Imagine a fictitious company, Delta Electronics, facing low Throughput in its assembly line. By analyzing their processes, they identified a bottleneck at the quality check stage. Delta then implemented an automated quality inspection system, which not only reduced the time taken per unit but also maintained high quality. As a result, their Throughput increased by 25% within six months.

Trends, Patterns, and Insights:

Historical Trends:

Analyzing the historical trends of Throughput can reveal a lot about a business’s operational efficiency over time. For instance, a steady increase in Throughput could indicate successful process improvements or technological upgrades. Conversely, a decline or fluctuation might signal operational challenges or market changes. This long-term view helps in strategic planning and forecasting.

Seasonal Variations:

Many businesses experience seasonal variations in Throughput. Retailers, for example, might see a significant increase during holiday seasons. Understanding these patterns is crucial for effective resource allocation and inventory management. Preparing for peak times and knowing when to scale down operations can optimize costs and maximize profits.

Predictive Insights:

With advancements in data analytics, businesses can now use historical Throughput data to predict future performance. Predictive models can help in anticipating demand, planning for capacity, and making informed decisions about resource allocation. This foresight is invaluable in maintaining a competitive edge in dynamic markets.

Next Steps:

After gaining a comprehensive understanding of Throughput as a KPI, it’s important to integrate this knowledge into your business strategy effectively.

Implementing Throughput Analysis:

Start by setting up a system for regularly monitoring and analyzing Throughput data. Ensure that your data collection is accurate and timely.

Continuous Improvement:

Use the insights gained from Throughput analysis for continuous process improvement. This could involve regular reviews, adopting new technologies, or revising operational strategies.

Integration with Other KPIs:

Throughput should not be viewed in isolation. Integrate it with other key performance indicators such as quality, customer satisfaction, and financial metrics to get a holistic view of your business performance.

Staff Training and Involvement:

Educate your team about the importance of Throughput and how they can contribute to its improvement. Employee involvement is crucial for successful implementation of any operational changes.

Review and Adjust:

Regularly review the impact of any changes made based on Throughput analysis. Be prepared to adjust your strategies as needed to ensure continuous improvement and alignment with business objectives.

FAQs

- What is Throughput in the context of business performance?

Throughput is the rate at which a company completes a process, task, or produces goods within a specified time frame, reflecting operational efficiency. - Why is Throughput an important KPI for businesses?

Throughput is crucial for measuring operational efficiency, identifying production or service delivery rates, and for optimizing resource utilization. - How do you calculate Throughput?

Throughput is typically calculated using the formula: Throughput = Total Output / Total Time. - Can Throughput be applied to service industries, or is it just for manufacturing?

Throughput is applicable in both manufacturing and service industries. In services, it could measure tasks completed, customers served, or transactions processed. - How does Throughput relate to other KPIs like efficiency and productivity?

While Throughput measures the rate of production or task completion, efficiency relates to the resources used, and productivity combines both output and efficiency aspects. - What are some common challenges in measuring Throughput?

Challenges include accurately capturing all relevant data, ensuring the data reflects true performance, and balancing Throughput with quality and cost considerations. - How can a business improve its Throughput?

Improvements can be made by streamlining processes, investing in technology and training, and regularly reviewing and adjusting operational strategies. - Are there any limitations or drawbacks to using Throughput as a KPI?

One limitation is the potential neglect of quality and cost factors. Focusing solely on Throughput might lead to compromised product or service quality. - Can seasonal variations affect Throughput?

Yes, many businesses experience seasonal fluctuations in Throughput, which should be taken into account for accurate performance assessment and planning. - How often should Throughput be measured and reviewed?

The frequency depends on the business type and operations pace. Some may benefit from daily monitoring, while others might find weekly or monthly reviews sufficient.